4,000 euros saved on paper alone

We interviewed our long-term client AS Rudus, whose core business includes the sale and transport of ready-mix concrete, granite aggregates, and concrete products. Our interviewee was Kaido Kivistik, Production and Technical Manager at Rudus.

How did the cooperation with Metrotec begin?

There was uncertainty about fuel consumption and mileage, and doubts about whether routes were truly optimized.

“We drove the routes ourselves, recorded distances in Excel, mapped routes on paper, and compared mileage using map software. The workload was heavy, and disputes were frequent. GPS tracking seemed like a good control measure. That’s why we contacted Metrotec OÜ, and we’ve had no reason to regret it.”

With Metrotec, it became easy to monitor route accuracy and keep fuel and time costs under control. Drivers can see the route to their destination on a tablet and use it for navigation.

“In our daily work, we often serve high-frequency sites where we deliver hundreds of loads. Even saving a few kilometers per trip can lead to significant fuel savings over the course of a day or an entire construction project.”

What developments followed?

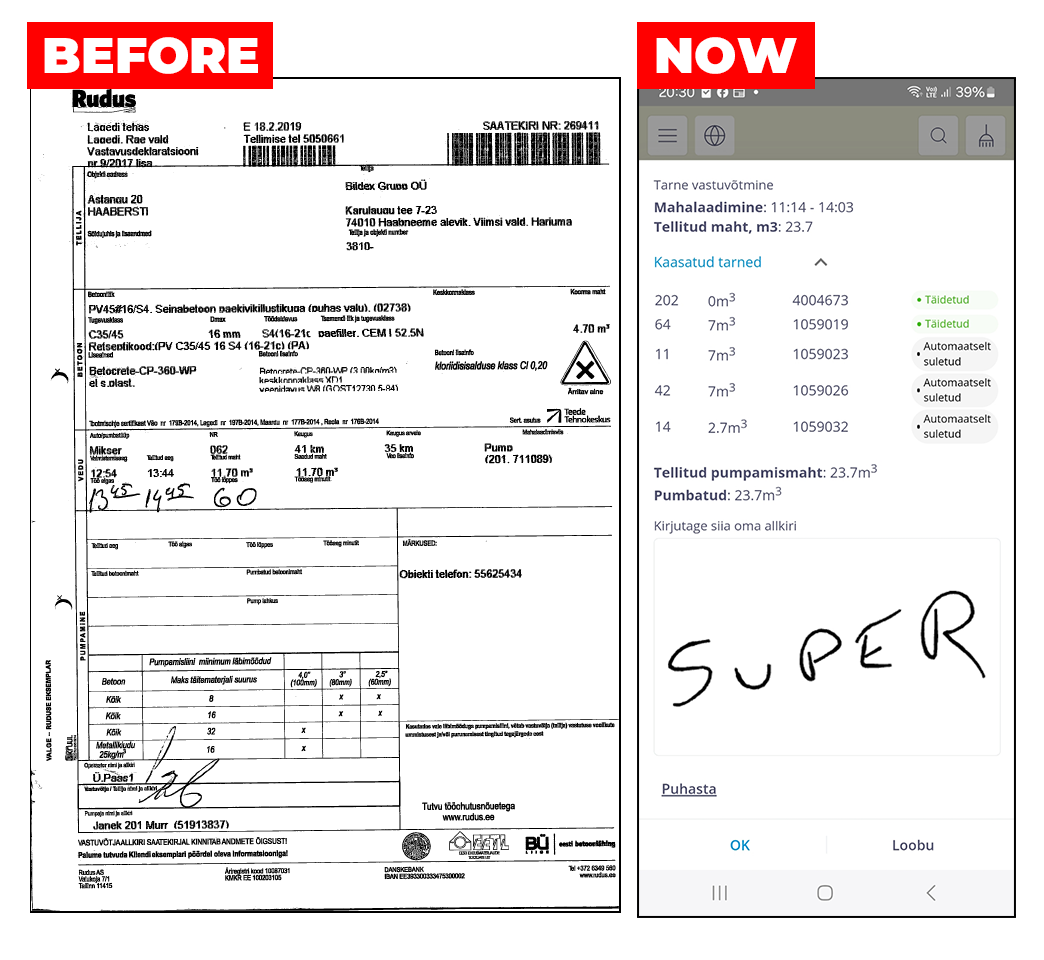

Today, we have fully switched to digital delivery notes and no longer use paper at all. Switching to digital delivery notes has brought clear benefits — for the environment, for costs, and for employees.

“At large projects, such as the Seaplane Harbour, where we delivered hundreds of loads per day, the amount of paperwork was enormous. Sometimes the sea wind would scatter the papers across the site, and we literally had to run around collecting muddy delivery notes one by one.”

Today, the pump operator hands over the day’s deliveries to the site manager with one simple action. On the tablet screen, the site manager sees a complete list of loads, including unloading times. They can track completed deliveries as well as those still on the way.

Today, the pump operator hands over the day’s deliveries to the site manager with one simple action. On the tablet screen, the site manager sees a complete list of loads, including unloading times. They can track completed deliveries as well as those still on the way.

The highlight? A single signature that confirms the work of multiple trucks for the entire day. As soon as it’s signed, the digital delivery note instantly arrives in the recipient’s email inbox.

The financial impact is also clear:

Previously, around €2,000 was spent every six months on carbon-copy delivery note books — €4,000 per year. That entire cost has now been saved simply by going paperless.

Checking delivery notes and settling accounts with subcontractors has become much simpler.

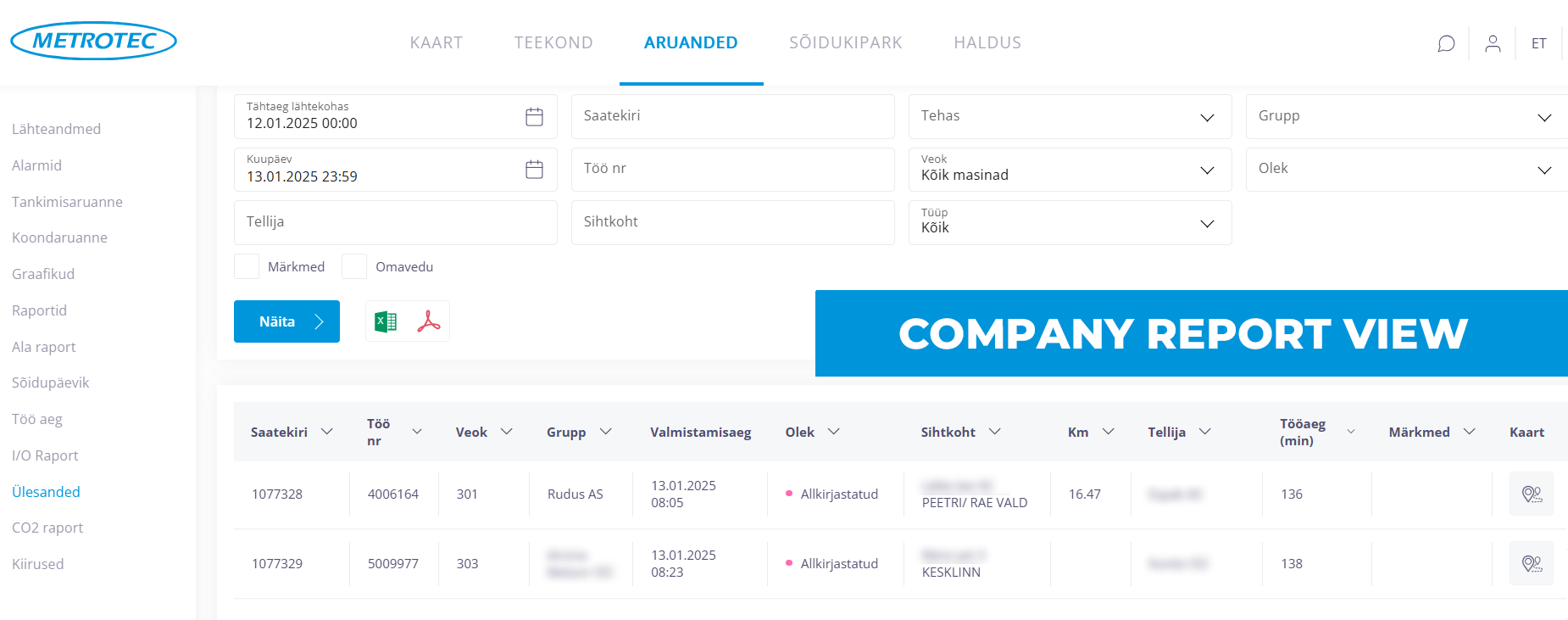

Trip data is already available in a ready-to-use format. With simple sorting and grouping, deviations are easy to detect. These are always discussed with drivers. Often, mistakes are human errors, and analyzing them in the system is convenient.

The data quality is high, and essentially the same reporting table is now used as the basis for next month’s internal forecasts.

How did drivers adapt to the digital system?

“Overall, things are working well. There’s always a risk that people resist new systems, and that happened with us too. We handled those cases personally and eventually reached a mutual understanding.

Although the average age of our drivers is relatively high, and some had never used apps before, we’ve managed well. Today, more than 90% fully understand the system.”

The app itself is simple. On-site training sessions were organized, and user guides were prepared. Drivers also share experiences among themselves. Switching from traditional paper documents to a fully electronic system is a major change, but one that has paid off.

Some subcontractors work with us only temporarily. Their vehicles use mobile devices that can be plugged into a cigarette lighter socket.

The Metrotec app runs on the driver’s tablet or phone, and by scanning a QR code, the driver can see assigned loads. This makes it easy to work even with drivers who are not permanent employees but whose services are needed temporarily.

Who benefits from Metrotec?

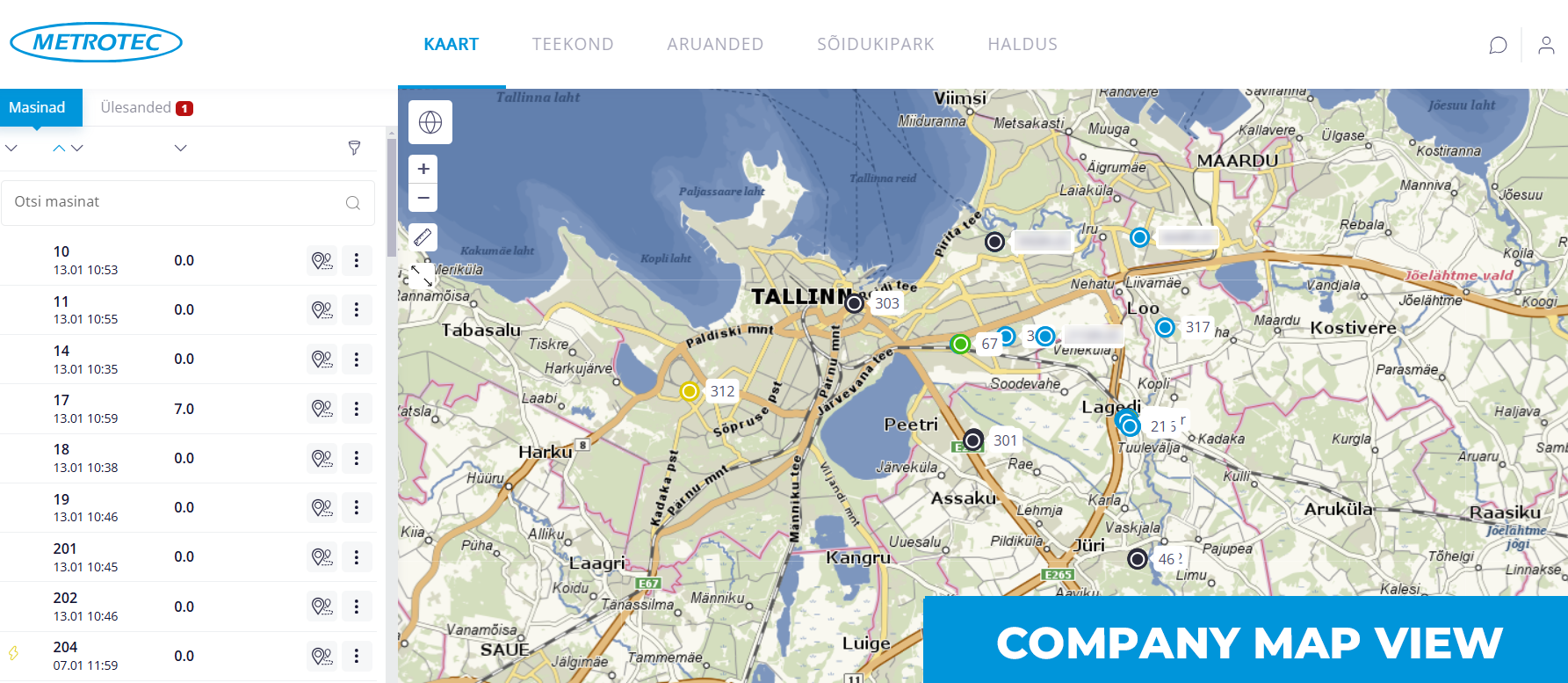

Around 10 office employees use the system daily, including sales secretaries, logistics managers, and management. “Our logistics software is quite old, so integrating it with Metrotec was a real challenge. Fortunately, it was done very successfully.” In the map view, it’s easy to see in real time where each machine is and whether it is moving or stationary.

Including drivers, around 70 people use the system. Some drivers are also business owners, so they have multiple views: a driver account and a company view.

“The main functionalities we get from Metrotec are real-time machine location, route tracking and timekeeping, digital delivery notes, and convenient electronic signatures.”

What could be improved in the future?

One future direction is enabling subcontractors to issue invoices themselves based on the same data currently used for reporting. The first step has already been taken; each subcontractor now has their own account and can access reports independently.

Another goal is implementing a mandatory daily vehicle inspection checklist. Drivers would not be able to start work before completing a digital maintenance check.

Currently, vehicles are parked at the end of the day and typically not inspected again until morning. However, systems and equipment should be checked daily — oil levels, washer fluid, brake fluid, wheel bolts, lights, and rear-view cameras.

There have even been cases where a wheel came loose during driving and was lost completely. Because of this, wheel bolt markers are used, and their inspection is required.

“It would be ideal if the system reminded drivers every morning to complete the checklist. Only after confirming it should they be able to start work.”

Main benefits and value

“It’s difficult to calculate the exact financial impact of monitoring dozens of vehicles, but compared to the past, I save a significant amount of time, and follow-up control is much easier. I simply adjust the tables and apply my own formulas.

Metrotec is a powerful tool — if you actively use its potential. It also helps eliminate human errors and intentional misuse.”

Clients expect us to arrive at the agreed time — and we generally meet that expectation. That reliability is one of our key advantages, and it can be verified directly in the system. For every load, the customer also receives a notification when it has been dispatched, which is very convenient for them.

Kaido Kivistik

Production and Technical Manager

AS Rudus

You can find more information about the task management module in this article: https://metrotec.ee/en/task-management-solution/

Fill out the contact form below, and we will get in touch with you. In the message field, please write: Task Management Solution.