Delivery of large-volume orders with a single signature upon completion of delivery

Rudus’ story began when concrete mixers started piling up at construction sites. The sites required many truckloads of concrete, but the customer was unable to receive the delivered concrete.

The plant operates on a fixed schedule, dispatching a new truck to the site every 10–15 minutes. Mixers can quickly congest construction sites, creating a risk of concrete spoilage and potential penalties. Project schedules may also be disrupted.

This raised the question of how GPS tracking could be used to manage the situation more effectively. Counting vehicles within a defined area and sending an alert when their number exceeds a critical limit is technically simple. The real challenge was ensuring that these areas are created and removed automatically, without user intervention.

The solution was to integrate the client’s order management system with Metrotec. When a load is created, a delivery location is automatically generated in Metrotec along with relevant additional information, and the location is placed under monitoring. If more vehicles than allowed gather at the destination, an alarm is triggered. The delivery schedule can then be adjusted, and the concrete distribution can be reorganized smoothly.

Once all orders have been delivered, the delivery location is automatically removed. The entire process runs seamlessly and is fully automated.

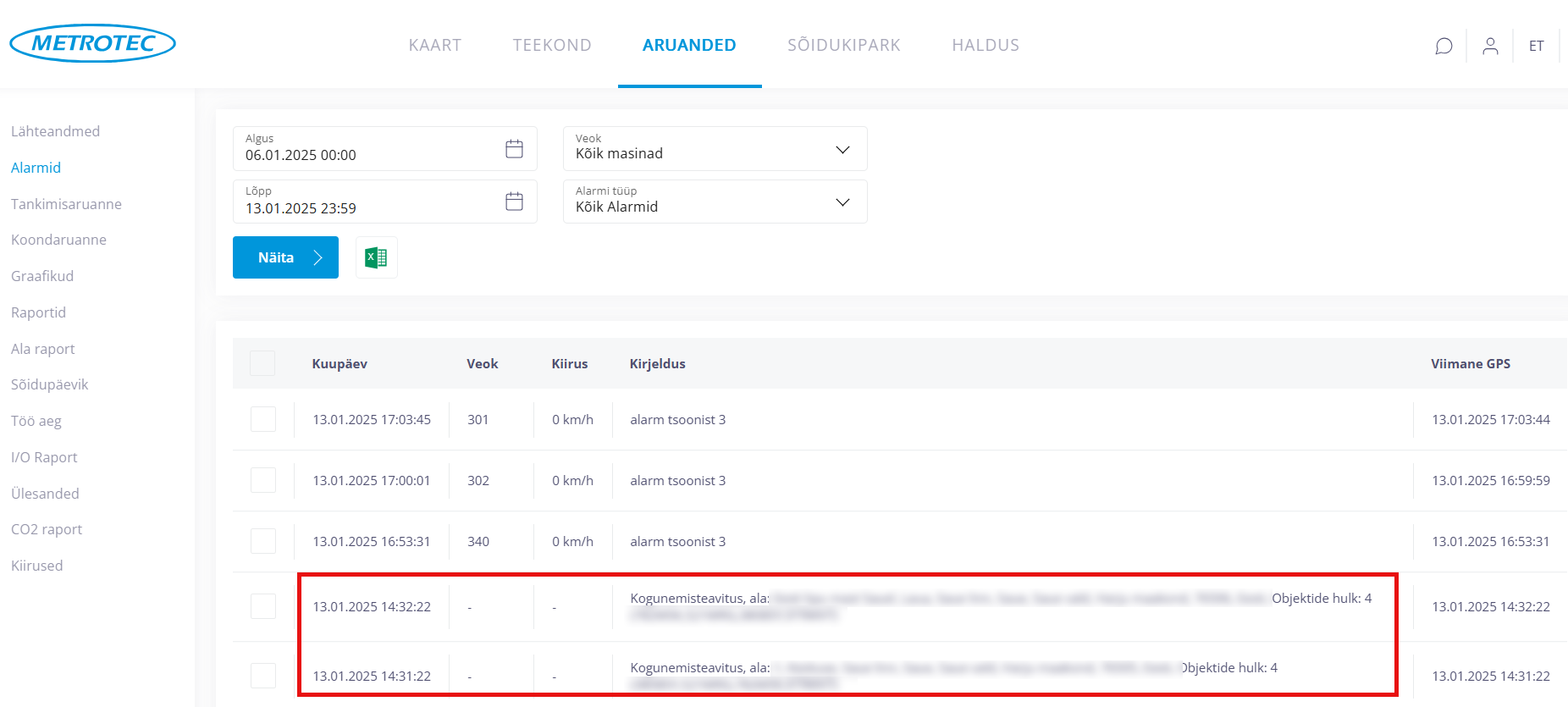

In the image below, the red indicator shows when an alarm is triggered, and the logistics manager receives a notification if the number of vehicles in the area exceeds the predefined limit.

The concrete order management system is a central and highly important tool at Rudus. It is used daily by everyone – production, logistics, drivers, and administration. The system tracks the entire order process, from planning to invoicing.

Each day, at least 200 loads pass through the system. This means managing 200 deliveries of varying distances, unloading operations, concrete additives, and delivery documents.

“Metrotec connects orders, drivers, accounting, and customers into one seamless system – completely paperless.”

What changed?

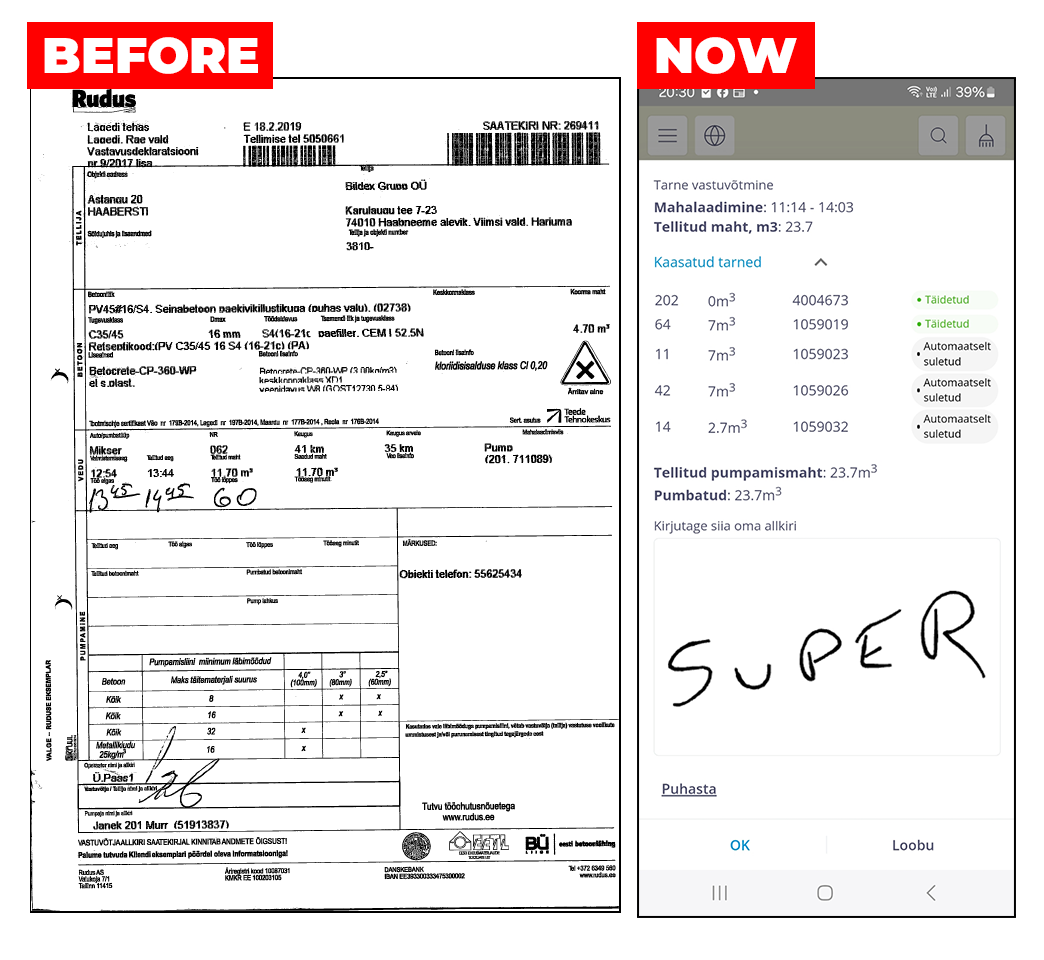

The paper disappeared. Simply scanning delivery notes and storing stacks of files was cumbersome.

The Standard Books business software was integrated with Metrotec. With a single click, a delivery note – or a batch of notes – is added directly to the invoice.

Handing over and receiving delivered goods and services became smooth. Delivery notes no longer got lost and reached the customer without delay.

Large deliveries became customer-friendly. A stack of papers, each needing a signature, was replaced by a single confirmation.

Arrivals and unloading times were automatically recorded. There was no longer a need to note these manually and enter them into the system later, improving accuracy and quality.

Automatic alerts were generated for vehicle congestion at sites, allowing logistics teams to respond quickly and reorganize deliveries more efficiently.

Notes from concrete drivers on additives and other details were systematically collected, providing a convenient way to track and invoice accurately.

In summary, there was a significant increase in quality.

How is it built?

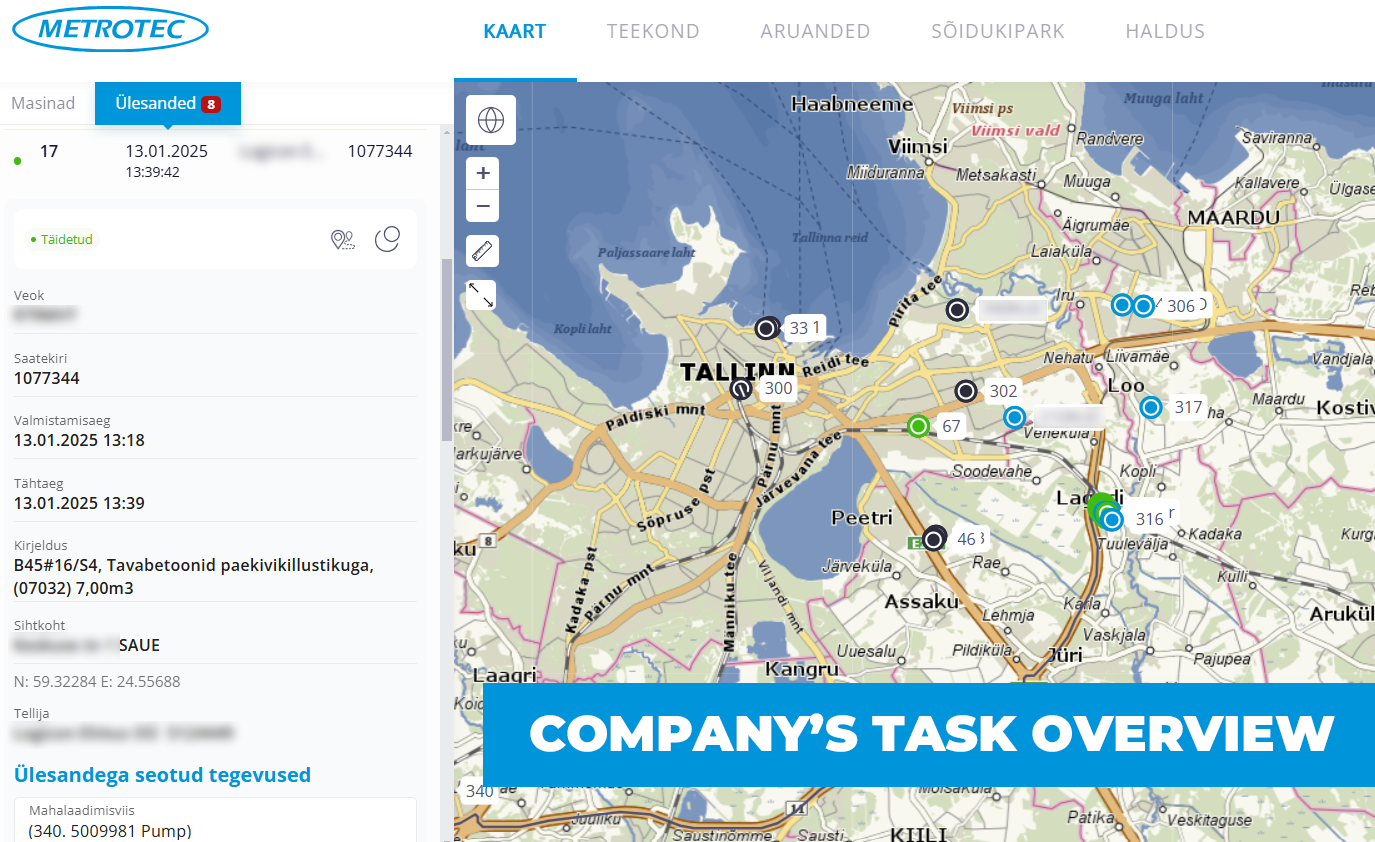

Each truck is equipped with a tablet, and every driver has a personal Metrotec user account. At the start of the workday, the driver logs into a specific vehicle and begins receiving delivery notes.

For every load, the order management system contains precise details: destination, delivery time, customer information, concrete specifications, and unloading instructions.

When the load is ready at the plant, the delivery information is automatically sent to the assigned truck’s tablet.

The driver receives a clear work order with all the necessary details for arrival and unloading. The navigation system guides the driver accurately and efficiently to the destination.

Logistics managers have full visibility of the entire process – which vehicle is handling which delivery, and the real-time status of each order.

Metrotec records the arrival time, calculates the distance driven, measures the unloading time, and adds this data to the delivery note.

Once the delivery is completed, the driver collects the customer’s signature. Metrotec then compiles the delivery notes into a file and sends them to the customer.

You can also read the interview with Rudus Production and Technical Manager Kaido Kivistik, who explains how implementing Metrotec has saved them €4,000 on paper costs alone.

You may also be interested in:

-

Recording of changes in operating status

It is common sense that measures to improve efficiency should be based on careful measurement and analysis. First, the work or service process should be broken down into a succession of operating statuses. The breakdown, definition and number of statuses will be different in different cases. What is important is the timely recording of the status and of its duration.

Read more -

Tasks

A work order citing a specific location and guidance is the first thing with any job. Only after it is in place can we start considering job performance and operational speed. Metrotec’s job management application links up the driver, the logistician, the customer and, where this is needed, also the accounting software.

Read more -

GPS jälgimine – iga samm saab kaardistatud

Autodele paigaldatavad GPS-jälgimisseadmed võimaldavad tänapäeval tohutult rohkem kui lihtsalt sõidujoone kaardile kuvamine. Millised on viimase aja trendid?

Read more