Monitoring machine operations using GPS devices: accurate, verifiable, and transparent

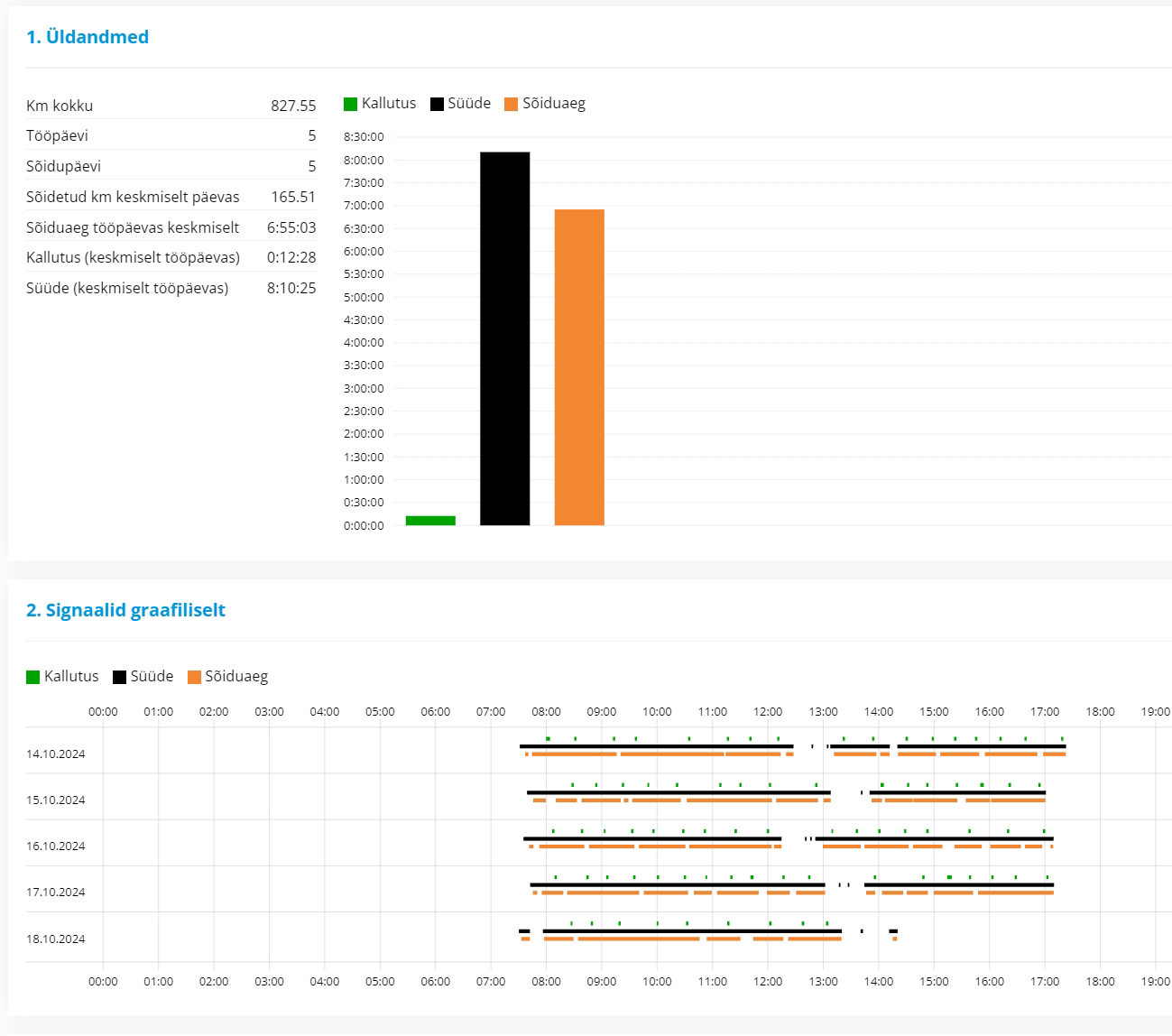

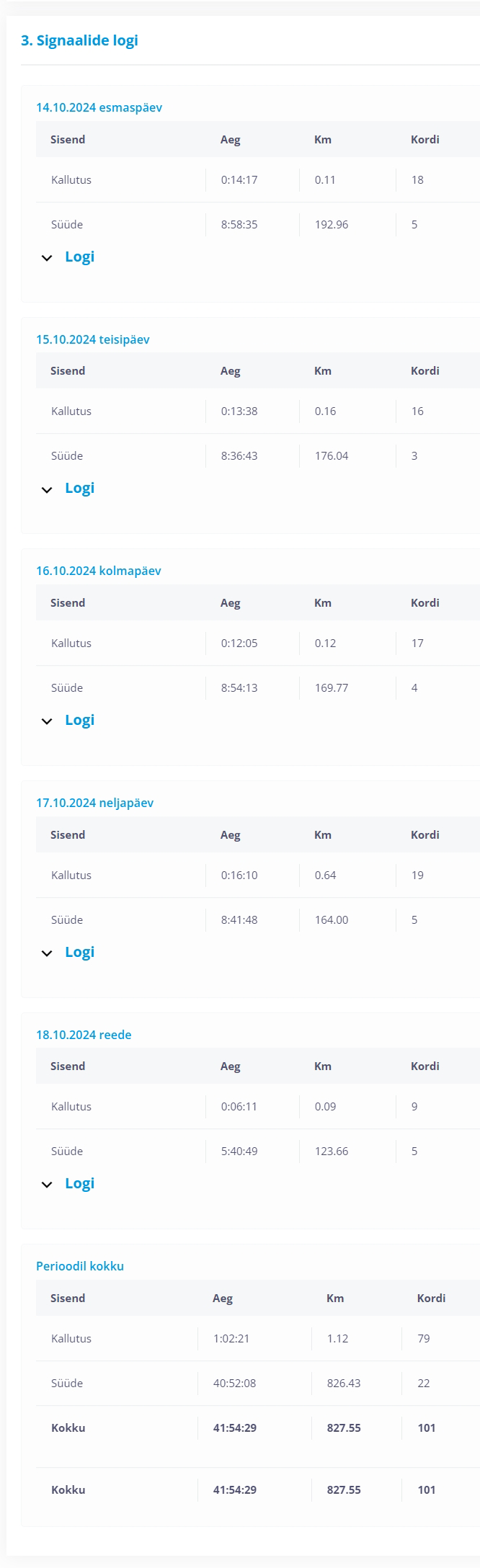

Beyond standard location and fuel monitoring, it’s increasingly important to track the efficiency of different machines. Analyzing this data allows you to optimize production or transport processes, making them more transparent and higher quality in the eyes of your company, employees, and clients.

For different types of machines, “processes” can mean different activities—crushers crushing, garbage trucks emptying bins, or dump trucks tipping loads. Reports and visual maps of these activities provide an accurate overview of the duration, location, and frequency of tasks (for example, how many times a dump truck tipped its load).

How does the system work?

An electric signal from the machine is connected to the GPS device, which interprets it as a “process.” For example:

- On crushers, it could be the activation of the feed conveyor.

- On loaders or excavators, a separate inductive sensor may be used.

- On garbage trucks, it could be the movement of the lifting arm.

- For dry material transport, it could be the activation of a hydraulic pump during unloading.

When the signal is triggered, the GPS device sends the information to the server, and the user interface displays clear, easy-to-understand reports about the machine processes.

Reports generated from the collected data include:

- Number of process occurrences

- Duration of each process

- Visual map of where the process took place

- Comparison of processes with actual engine running time, distance traveled, or time

- Fuel consumption during active processes

- And more

Depending on the type of machine, this data provides detailed insights to plan tasks more efficiently, offer more transparent services, and solve operational issues quickly.

Here are some examples based on machine types.

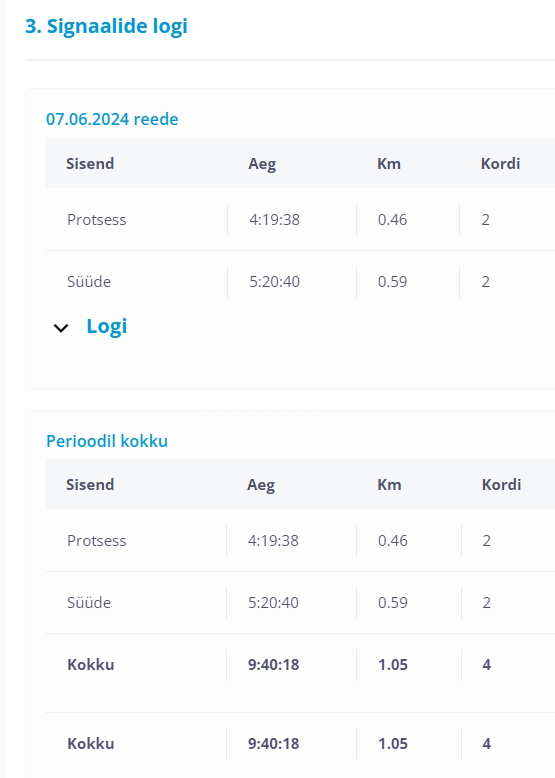

Crushers and soil screens: understanding actual work

For crushers and soil screens, it’s important to distinguish between engine running time and actual work being done. This affects work planning, calculating the volume of crushed or screened material, cost accounting, and invoicing to the end client.

Depending on the machine, information about actual work comes from various sensors, agreed upon with the client in advance. For example:

- On crushers, the feed conveyor signal or crusher operation is monitored.

- On soil screens, the screening table activity is tracked.

These signals indicate a real process – actual work being done and value being created. In addition to process duration, the system shows fuel consumption during active work.

Benefits:

- Accurate work overview: data on actual working time and fuel used.

- Reports and visualization: clear, transparent reports for each machine, with processes mapped by duration and location.

- Cost control: distinguishing real work from idle engine time prevents incorrect hour calculations, helping service providers accurately assess when productive work occurs and when the machine is idling.

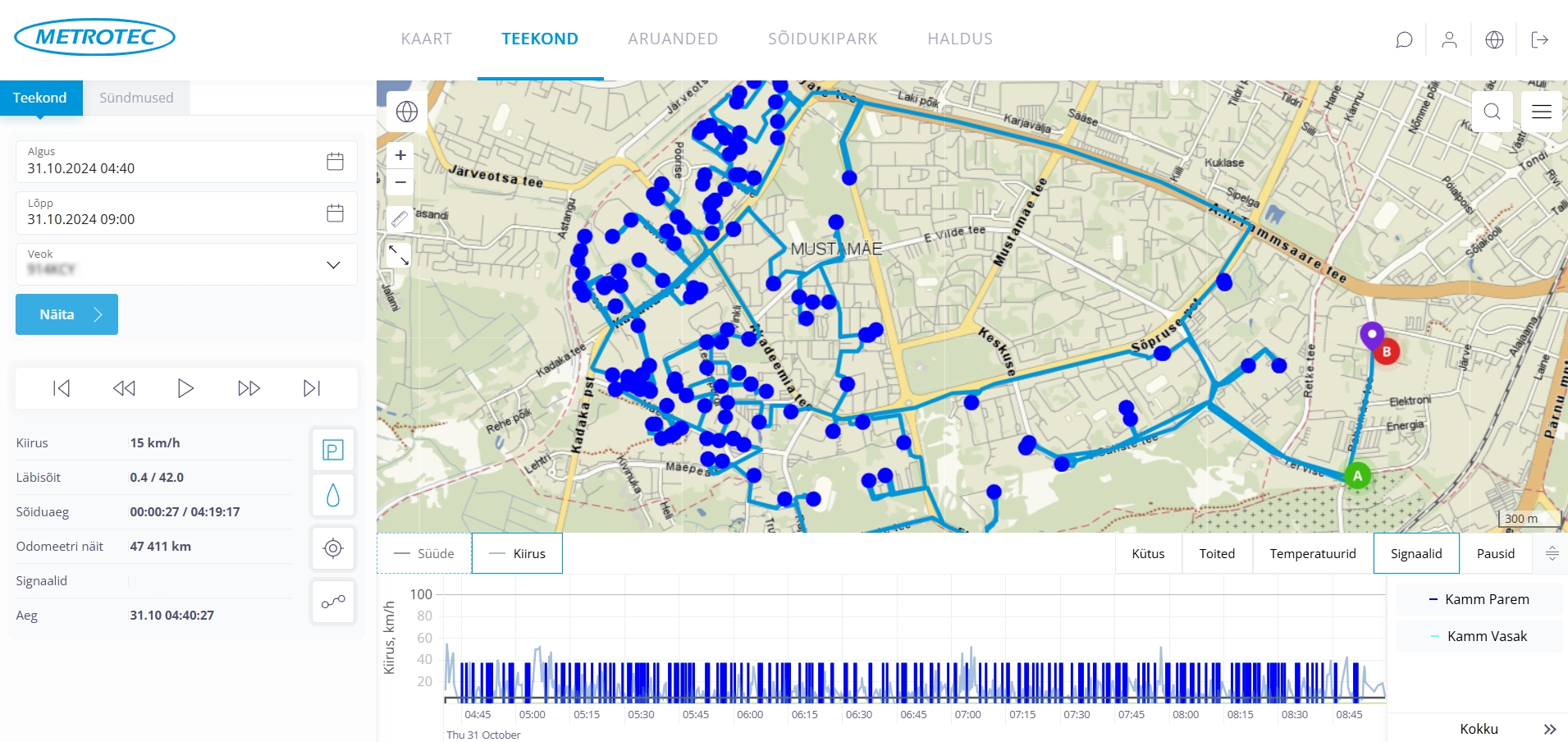

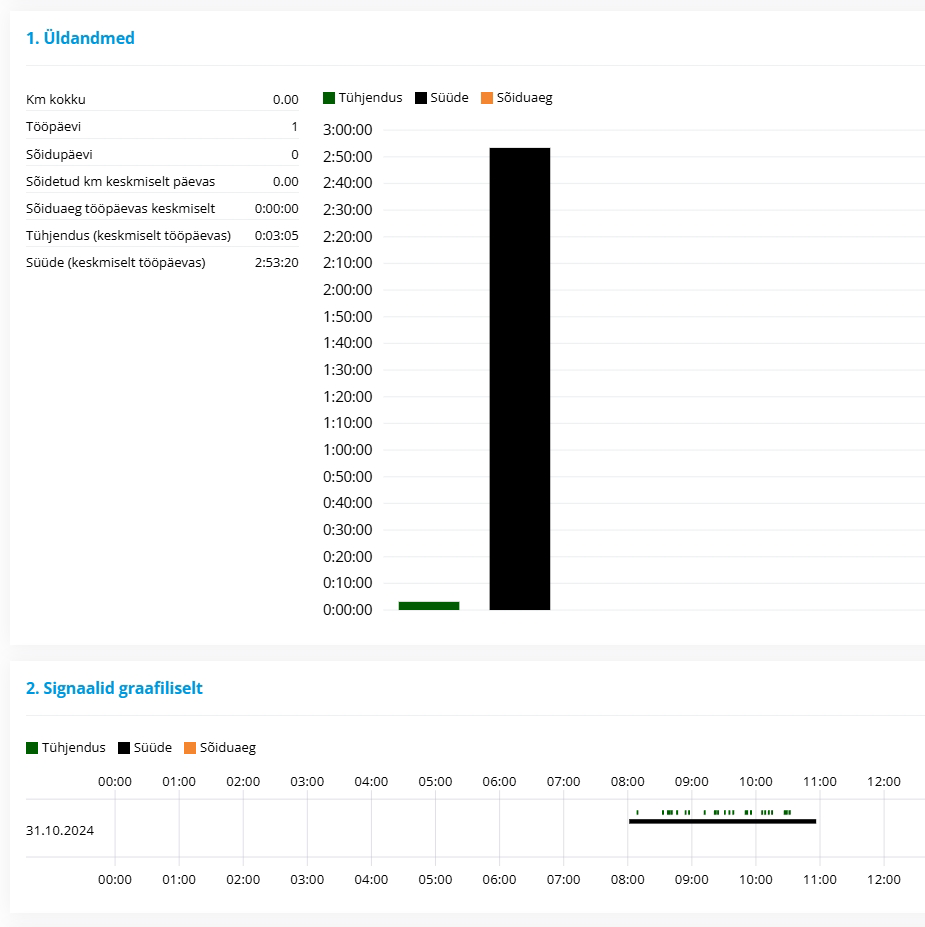

Garbage trucks: monitoring bin emptying

Tracking the movement and work processes of garbage trucks is important not only for efficient logistics but also for good customer service. Situations where customers are unsure whether their bins have been emptied can easily lead to disputes.

Garbage trucks usually use a lifting mechanism (a comb, winch, or crane) to lift and empty the bin. When this mechanism is activated, a signal is sent to the server. The report shows the exact time and location of the signal.

If the lifting mechanism does not generate a signal, additional sensors can be installed, for example, in the hydraulic system. When activated, these sensors send a signal confirming that the bin has been emptied.

Key benefits:

- Time and location of emptying

The exact time and location of each bin emptying are recorded, providing a clear overview of all work completed during a day or week. - Dispute resolution

If a customer questions whether their bin was emptied, customer support can provide clear evidence of the completed service, significantly reducing time spent on disputes. - Information on the used lifting mechanisms

If a garbage truck has multiple lifting mechanisms (e.g., left and right), their operation is recorded separately. This allows for a more detailed analysis of the truck’s workflow. - Daily workload analysis

Based on collected data, it is possible to assess the truck’s workload (number of bins emptied) over a day or any selected period. This helps optimize workflows and distribute work more evenly between vehicles when needed.

Loaders and excavators: measuring activity frequency and workload

Measuring the actual work performed by loaders and excavators is often a major challenge. In most cases, the machines do not have built-in sensors or available signals that indicate real operational activity.

To monitor work processes, separate inductive sensors are used. These sensors detect and record the movement of the lifting arm or digging boom. The sensor placement is agreed with the customer to ensure the most accurate and relevant information about the specific process the customer needs to monitor.

Tracking work frequency and workload

Reports enable accurate monitoring of how often a machine is working and how heavily it is loaded. For example, the system can record how many times a loader lifts material to the loading height.Comparing engine runtime with actual work

In many cases, the engine runs even when no real work is being done. By collecting data on the movement of the lifting or digging boom (the actual work process), it becomes possible to compare process duration and frequency with engine operating hours.Material movement calculation

The system counts the number of repetitions, such as how many times the loader’s lifting arm reaches the loading height. If the bucket capacity is known, the moved material volume can be calculated based on the number of lifts.

Example: a 1 m³ bucket lifted 10 times means 10 m³ of material has been moved.

Overall, this solution allows much more precise monitoring of loaders and excavators, providing clear insight into machine workload, efficiency, and the total volume of material moved.

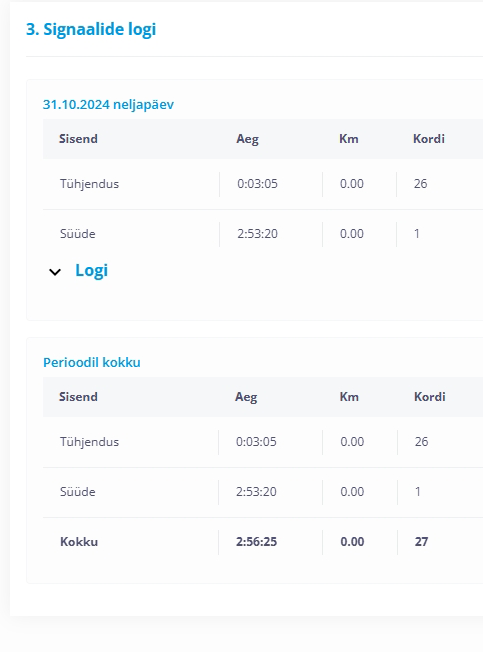

Dump trucks: tracking the number of trips and transported material volume

For dump trucks, it is important to monitor the number of trips and the volume of transported material to ensure accurate records for internal analysis and customer billing.

The most effective way to track trips is by using sensors that detect tipping events. Sensors installed on dump trucks register each body lift, indicating that material has been unloaded. Every time the driver activates the tipping button or lever, this information is sent to the server via the GPS device. Reports show the time, location, and duration of each tipping event.

Key insights and benefits:

- Trip counting

Each tipping event is counted as a separate trip, giving customers a clear overview of how many transport runs were completed. - Actual trips vs. planned volumes

By knowing the number of tipping events, it is easy to compare the actual number of completed trips with the number of trips ordered. In many cases, it turns out that fewer trips were ordered than were actually completed. - Transported material volume

If the dump body capacity and the number of trips are known, the total volume of transported material can be calculated easily. This information is essential for logistics planning, operational control, and accurate customer invoicing.

By using GPS devices and machine-based signals, it is possible to gain a precise overview of machine operations—whether crushers, garbage trucks, excavators, dump trucks, or other heavy equipment. The system collects real-time data on when, where, and how often work is performed and generates clear, easy-to-understand reports.

Process monitoring not only helps improve service quality and keep costs under control, but also enables fast problem resolution and provides customers with a more accurate and transparent service.

You may also be interested in:

-

Recording of changes in operating status

It is common sense that measures to improve efficiency should be based on careful measurement and analysis. First, the work or service process should be broken down into a succession of operating statuses. The breakdown, definition and number of statuses will be different in different cases. What is important is the timely recording of the status and of its duration.

Read more -

Tasks

A work order citing a specific location and guidance is the first thing with any job. Only after it is in place can we start considering job performance and operational speed. Metrotec’s job management application links up the driver, the logistician, the customer and, where this is needed, also the accounting software.

Read more -

GPS jälgimine – iga samm saab kaardistatud

Autodele paigaldatavad GPS-jälgimisseadmed võimaldavad tänapäeval tohutult rohkem kui lihtsalt sõidujoone kaardile kuvamine. Millised on viimase aja trendid?

Read more